ABOUT "STAVBY OMO"

The company was founded in 2009 by Jaroslav Číhal to provide professional services in areas such as the installation of road restraint systems (crash barriers) and specialty construction activities in building and road construction. The new company capitalizes on Jaroslav Číhal’s knowledge and practical experience in the industry where he worked, among others, as an independent contractor for more than 30 years, and draws on them even today in its innovative approaches. The family team that makes up the core of the company is supported by highly experienced employees and skilled external collaborators.

We offer currently complete services in these key areas:

Installation of road barriers:

Installation of road barriers is one of the main activities in our company with more than 15-year history. In the beginning, we installed traffic barriers according to the client's specification (especially products of Arcellor Mittal). Since 2007 when the company launched its own type of road barriers (bridge barrier MS4/H2 and bridge railings crash barriers ZMS4/H2 and ZMS4/H3), we have prioritized OMO road barriers because of their excellent technical parameters for intended applications (bridges, along roadsides, retaining walls, etc.).

We supply and install road barriers not only in the Czech Republic, but also along the roads in the Slovak Republic and EU member states where they have the appropriate approvals and homologation. We act as subcontractors for big construction companies such as SKANSKA, EUROVIA, STRABAG, PORR, METROSTAV, COLAS CZ, SWIETELSKY stavební, OHL ŽS and HOCHTIEF, but also as a contractor to road owners, i.e. the state, county, city or private entities.

The services for our customers include:

- consultancy in designing or selecting road restraint systems

- delivery and installation of the selected type of the restraint system specific to the needs of the construction project, including necessary modifications (e.g. surface treatment, colours, etc.), adjustments and incorporation into the surrounding structures

- manufacture of non-standard elements (e.g. posts at different inclination angles), including their development and testing according to the customer’s specifications (the company has its own test facility)

- repair of road barriers (crash related damage, natural disasters, age-related deterioration) supplied and installed by OMO or some other company (by prior arrangement)

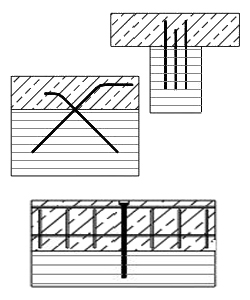

Drilling into construction materials:

Drilling is performed using diamond core bits of high quality. Because core bits are routinely cooled by the water, the technology is virtually dust-free.

Core drilling of materials by OMO Stavby - key data:

- diameters from 10 mm to 1000 mm

- practical experience with drill holes up to 12 m deep

- drilling at precisely set angles in horizontal or vertical planes (i.e. in floors, walls, ceilings)

- electric or hydraulic drills

- drilling into various kinds of building materials - concrete, reinforced concrete, stone, various kinds of masonry, wall and floor tiles and material combinations

- upon request, we will arrange for structural analysis, required measurements

High strength anchoring:

We use several anchoring technologies according to their suitability at the site.

Steel expansion anchors OMO

They are our certified patented invention and product since the early 1990s.

Steel expansion anchors are used in particularly demanding applications requiring immediate full tensile capacity of both the anchor and the material into which it is mounted. Our anchors are fully proven in a number of extreme applications and have also been used, e.g., in a number of crash barrier certification tests.

Resin-based anchoring systems

are comprised of an anchor - mostly a threaded rod of appropriate strength parameters - and resin-based grout that fixes the anchor in the hole.

Anchors – we use either own proprietary certified threaded rods (strength class 5.6), anchors from reputable manufacturers (e.g. Hilti) or other anchors requested by the customer (various bars, rods, hooks, and other anchoring systems).

Anchor putty – we mostly use Hilti systems or systems according to customer’s requirements and structural calculations.

Cement-based anchoring systems

Probably the most economical anchorage option. It consists of the anchor proper and anchoring grout, which is polymer-modified mortar (e.g. Groutex products).

Wall sawing:

Wall saws with diamond sawblades are used to make precision cuts in existing structures, cut accurate large openings in walls, remove sections of structures, etc.

Wall sawing by OMO Stavby - key data:

- cutting depth of up to about 600 mm, or as agreed upon

- cutting length according to client requirements

- very precise cuts with smooth walls when guide rails are used

- cutting at precisely set angles in horizontal or vertical planes

- electric or hydraulic saws

- different kinds of building materials

Diamond wire sawing:

Diamond wire sawing is a modern and cost-effective technology for cutting and removing large sections of concrete structures. Using a system of suitably positioned and attached pulleys, an electrical unit drives a special high-strength cable fitted with beads with diamond grit through the structure to be cut.

Diamond wire sawing by OMO Stavby - key data:

- virtually unlimited cut depth and area

- cut length according to client requirements

- precision cuts with relatively smooth walls (with possibly minor irregularities caused by the cable)

- cutting at precisely set angles in horizontal or vertical planes

- different kinds of building materials

Coupling and reinforced structures:

Coupling and reinforced structures are rehabilitation technologies whose aim is an improvement of the original parameters (e.g. tensile, bending or pressure strength) of the structure being repaired. For these purposes, steel components (anchors, rods, nets, etc.) or composite materials (most frequently carbon fibres in a resin binder) are used. These elements are then fixed mechanically (expansion anchors OMO) or chemically in the construction.

Hydraulic splitting:

A demolition technique whereby the building material is gradually disintegrated by the action of hydraulic piston pushing on wedges inserted in the material.

It is an alternative to traditional demolition techniques using hand-held demolition hammers or large demolition machines. It is a more friendly technology for the immediate surroundings (eliminates shocks to the substrate material that might cause structural instability of nearby structures), and enables demolitions in places inaccessible to a large demolition equipment.

Hydraulic splitting by OMO Stavby - key data:

- maximum achievable force - 2800 kN

- area treated- no limitations

- depth of the structure – also no limitations thanks to the gradual breaking up of material

Sale of special construction tools:

We provide for our customers OMO steel anchors, anchoring elements of crash barriers and other high-quality tools.

We in OMO strive for customer satisfaction in all the products and services we deliver. We offer a personal approach to every customer and give to their disposal all our long experience in carrying out demanding and specialized construction projects.

If you have any question, please contact us using the web form or via email.

Dipl. ing. Jaroslav Číhal.